leading SHOWER DOORS MANUFACTURER & Supplier

Shower Doors Product Series

As a professional Glass Shower Door manufacturer, we have a full series of shower door, such as Wheel, Framed Shower Door, Frameless Shower Doors and Bathtub Screen series.

Sliding Shower Door

Frameless Shower Door

Sliding Shower Door

Bathtub Shower Door

The Basic Knowledge Of Shower Doors

The shower door is a door of the shower room, the majority of them are glass doors. Shower room: separate shower compartment, modern homes are becoming more and more demanding in terms of bathroom facilities, and many families want an independent bathroom space, but due to limited sanitary space in the living room, bathing facilities can only be placed in one room with sanitary ware. Shower cubicle makes full use of a corner of the room, and the shower range is clearly delineated by a fence to form a relatively independent shower space.

1. Functions

Today, shower door have become an important part of the bathroom space, It has the following main functions.

A. Wet and dry separation function

Home decoration is becoming more and more gorgeous and noble, a large number of solid wood doors, wood flooring, closet applications, requiring washrooms to distinguish between dry and wet areas, in the wet area to complete the shower space. So the biggest function of the shower door lies in the role of waterproof.

B. Function of keeping warm

Due to the widespread use of natural gas or gas water heaters, the bathroom is required to be well ventilated, and the shower can effectively block the cold air, and the hot steam forms a wrap around the body when bathing, thus playing a role in keeping the body warm.

C. Decorative function

A set of atmospheric and beautiful shower door can make the whole bathroom style more coordinated, play a good decorative role in home improvement, highlighting the owner's personality and extraordinary taste.

2. Shower Shape

Return

Arc

Corner

Inline

3. Frame Type

Framed

Semi-Frameless

Frameless

4. Open Style

For the shower doors open style, we have Swing, Sliding, Rolling, Fold.

Swing

Sliding

Fold

5. Glass Finishes

Clear

Easy-Clean Glass

Acid Etched Glass

Wired Glass

Frosted Glass

Coated Glass

Frosted Glass

Laminated Glass

Filmed Glass

6. the Roller of shower doors

7. The hardware of shower door

The generally hardware of shower doors are Handle, Hinge and Pull rod.

Shower Doors Handle

Shower Doors Hinge

Shower Doors Pull rod

In regard to material of hardware, JATAII was adopted 62# Copper and 304 Stainless Steel.

Copper

Copper parts —— 62 copper is one of the copper alloys, 62 is the standard, the higher the standard the higher the copper content, but also the higher the cost, such as the big bend in the shower door, it is necessary to use 62 copper or higher standard, otherwise the toughness is not enough bending easy to produce cracks or fractures. Another factor that affects the quality of copper parts is the quality of plating. All the plating parts of SHKL shower door (including plastic parts) must ensure seven layers of plating, the first layer of alkaline copper plating, the second layer of rubber copper plating, the third layer of acid copper plating (The purpose of plating three layers of copper with different properties is to clean several times and to trim and fill the tiny pinholes on the surface of the copper parts.), the fourth layer is plated with semi-gloss nickel, the fifth layer is plated with full-gloss nickel, the sixth layer is plated with nickel front (Because the surface of such element as nickel is honeycomb, it must be plated again with two layers of nickel of different nature in order to correct the concave points with each other, so as to avoid quality problems such as black spots and pinholes on the surface of the product, Nickel is a high-cost material, at $32,000/ton), and the seventh layer is plated with chromium to prevent corrosion and maintain brightness and improve hardness and wear resistance. The surface is also treated with electric paint, which is more wear-resistant and less likely to be scratched. SHKL’s electroplated parts pass the acidic salt spray test for 24 hours (Exceeding the national standard of enterprise standards), there will be no black spots, blistering, delamination and other undesirable phenomena on its surface, The main product series that widely use copper parts are: 65, 66, 67, 73, 80.

Low-grade shower door more often use lower standard copper alloy fittings, and the quality of plating does not meet the requirements of the national standard, and even more far from the plating quality of SHKL, There are also many manufacturers in the selection of materials with zinc alloy, aluminum alloy or plastic parts. Zinc alloy weather resistance is poor, the service life of zinc alloy handles on windows and doors generally breaks within two to three years or so, and the aluminum alloy and plastic grade is lower. In the design structure of the accessories, all the wall fixing clips and glass clips of SHKL shower door can be adjusted back and forth to correct the error of the wall construction, and the low part of the glass and the side all use waterproof rubber strips with, one is good waterproof effect, the other is to protect the glass, prolong the service life of the product. But low-grade shower doors is purely patchwork, product structure is not rigorous, jerry-built, poor waterproof effect, and short product life.

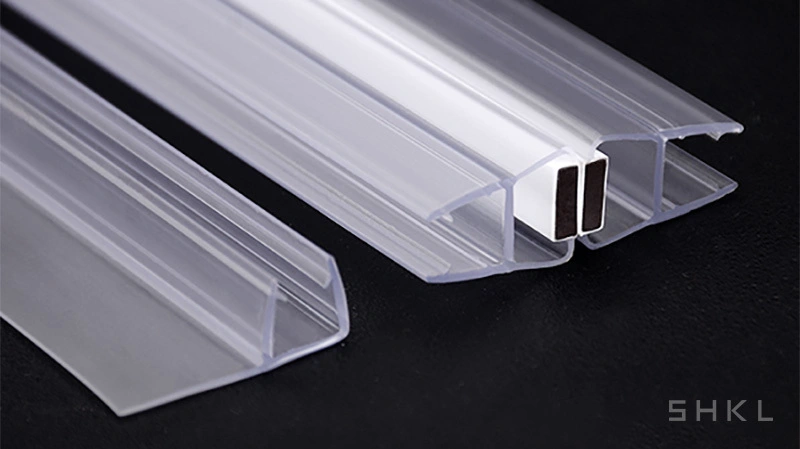

8. Adhesive Strip

9. Base

The Production Process of JATAII Glass Shower Doors

Shower door are made up of two main parts: the glass and the profile. Here is a detailed description of how glass and profiles are manufactured by us.

1. The Glass Process of Shower Door

About Glasses

Principle of tempered glass: It is processed by tempering furnace at high temperature to form a compressive stress layer on the surface of the glass, the glass itself has a high compressive strength and will not cause damage. When the glass is exposed to external forces, this pressure layer can partially offset the tensile stress and prevent the glass from shattering, although the inside of tempered glass is in a large state of tensile stress, but the internal defects of the glass do not exist and will not cause damage, thus achieving the purpose of improving the strength of the glass.

Tempered glass is much more flexible and stronger than ordinary glass, a piece of tempered glass of 1200mm×350mm×6mm can have a bending deflection of up to 100mm after the force is exerted, when the external force is removed, the original shape can still be restored, while ordinary glass bending deformation can only have a few millimeters.

The quality of the original glass is affected by the refining equipment, technology and process of the original glass flake factory, and its quality varies. Poor quality of the original flake often appears vapor bubbles, pinholes, black spots, white spots and foggy feeling (poor permeability), etc.

Tempered Glass Process

Glass Sheet

Automatic Punching

Opening (Cutting)

Printed & Cleaning

Edge Polishing

Tempering

In addition low-grade shower door in addition to the original piece of poor, but also mainly exists in the glass deep processing plant (glass factory) equipment, technology, techniques, management and other aspects of poor, such manufacturers of low production costs, but poor quality.

Poor quality tempered glass not only affects the aesthetics of the product, but also has a very low safety factor, such as uneven tempering, but once broken particles are large, with sharp sharp corners, which is extremely damaging to humans. The potential dangers are even greater with semi-tempered or even non-tempered glass, so we recommend that customers choose a product with quality assurance when purchasing a shower door.

The certifications of SHKL shower doors glass:

Rich Experience In Market

The Technology Of Laminated Glass Is Our Patent

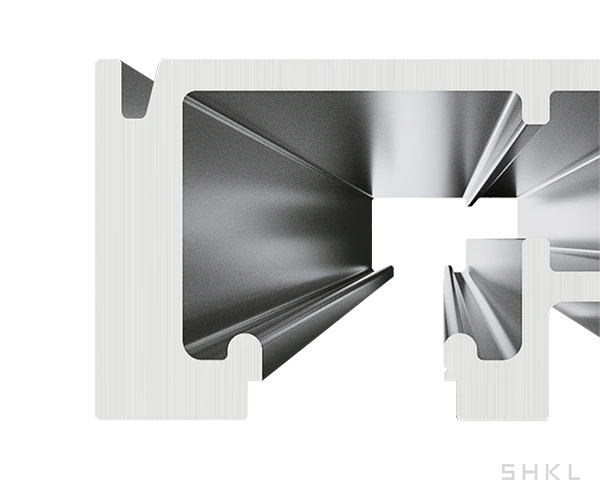

2. The Aluminum Profile Process of Shower Door

Selecting high quality aluminum and the way to compare aluminum:

The Oxidation Process Of Shower Door Aluminum Profile

Step 1: Material selection

Purpose: To distinguish different aluminum oxidation colors: brushed, bright silver etc.

Step 2: Polishing

Purpose: To remove oil from the surface of aluminum, make aluminum profiles brighter and stronger adhesion of the oxide layer.

Step 3: Racking

Purpose: To distinguish different oxidation color requirements and prepare for the next step of the process.

Step 4: Clean

Purpose: To clean aluminum by low concentration of nitric acid, phosphoric acid and sulfuric acid to further remove surface grease and make the oxidation better effect.

Step 5: Oxidation

Purpose: to make the aluminum surface coloring, and the formation of dense oxide film, strengthen the surface brightness of aluminum, and make it stronger corrosion resistance (Note: SHKL shower aluminum oxide film thickness of 12-15μ, much higher than the other general brand 8-10μ).

Step 6: Sealing

Purpose: To convert the oxide film from a large molecule structure to a small molecule structure to enhance the effect of oxidation.

The Cost Factor For Shower Doors

As a professional manufacturer of shower door, in addition to making products that satisfy our customers, we also need to provide a set of services the customers are comfortable with. Therefore, our quotation is meticulous. For next, please read below several factors that affect the price.

1 Glass thickness

The currently common glass thickness of shower door products are 6/8/10/12mm.

Because the thicker the glass is processed, the higher the cost (the processing process is more complex and time consuming, in addition to the higher cost of manual lifting).

So the thickness of the glass is affecting the price.

3 Easy-clean Glass

Easy-clean glass has many names (nano glass, self-cleaning glass, technology glass, super clean glass). It is a general term for a special coating applied to the glass surface, making it difficult for dust or dirty liquids (including liquids containing water or even oil) to adhere to the surface of the glass, or to be washed off by water relatively easily, so that the glass surface is very easy to keep clean.

Currently, there are single-sided easy-clean treatment and double-sided easy-clean treatment, and the prices of both are different.

5 Glass screen printing process

General screen printing white or black, can also screen printing two-color black + white, generally not recommended to do with color (blue / yellow) because of color deviation.

The current screen printing types are: clean glass screen printing (single color), clean glass spray white oil/black oil, white screen/dual color.

7 Glass masking process

After the tempering is completed, the frosted surface is formed by chemical potion corrosion, thus achieving the effect of blocking the line of sight.

At present, there are: single-sided sanding, double-sided sanding, process sanding

9 Aluminum profile color change

Bright silver, matte silver, sand silver, brushed are the basic colors, no additional charge.

The following colors require additional charges, other colors, please consult customer service.

Silver to checkered

Silver to gold

Silver to rose gold

11 Shower door with extra shelves

There are two types of shelves with different prices as follows:

Standard single shelf

Door shelf

2 Color of glass

If you don’t want the color of Clean, the color of the glass can be changed, the common change colors are: gray glass/tea glass/blue glass. Other colors are also available.

4 Glass explosion-proof film processing

6 Glass sanding process

After the toughening is completed, a frosted surface is formed by machine polishing, thus achieving the effect of blocking the line of sight.

Currently available: single-sided sanding, double-sided sanding, process sanding.

8 Glass coating

Coated glass is coated with one or more layers of metals, alloys or metal compounds on the surface of the glass, which provides good thermal insulation properties.

What is the difference between the effect of coating and screen printing?

Plating is mirror coating, silkscreen is a pattern printed on the glass surface, without reflection.

10 Stainless steel color change

Chrome to gold

Chrome to rose gold

12 Wooden rack packaging

Wooden rack packaging, refers to the carton packaging in addition to an extra layer of wooden frame, in order to protect the safety of the product, to avoid damage made in the process of transportation.

The Cost Factor For Shower Doors

Furthest reduce broken during the transportation as much as possible, also passed drop test.

1.Protect glass with

4.Standard package

2.Pack glass with PVC bag

5.Strong carton package

3.Standard accessories

6.Arrange plywood

Want To Purchase Too?

The Cooperation Process of Shower doors

(JATAII Service Process)

As a professional shower door manufacturer, In order to service our customer well, In order to service our customer well, In order to service our customer well, we have a completed service system and process. A completed service process can help customer save a lot of time.All of cooperated customers are satisfy to our service and have a long term and stable cooperation relationship.

1. Demand Communication

Communicate the product details and requirements with customer.

2. Solution Provide

JATAII technician provide production drawing and quote, accept EXW, FOB, CIF.

3. Solution Confirm

Confirm the plan.

4. Sample Production

Painting cabinet (15 days) Melamine board cabinet (7 days).

5. Sample Confirm

Further communication and final confirmed.

6. Bulk Order Confirmation

Sign final PI and arrange deposit (T/T).

7. Order Production

Arrange the production by our smart production system. Painting cabinet (45 days). Melamine board cabinet (30 days).

8. Provide Promotion Materials

JATAII designer provide product 3D rending picture , video, etc. to customer.

9. Order Inspection

Arrange products 100% inspection by our professional QC team.

10. Packaging & Storage

Packing the goods and arrange warehousing, manage storage by ERP system, keep all products in and out in orderly.

11. Balance Payment & Delivery

Arrange the loading after received balance payment.

12. Guidance Service

Provide product installation and maintain guidance.

The Company Introduction,

Give You A Clear Understanding For JATAII

In order to service our customer well, we have a completed service system and process. A completed service process can help customer save a lot of time.

All of cooperated customers are satisfy to our service and have a long term and stable cooperation relationship.

About Us

JATAII was founded in 2004 and is headquartered in Foshan, Guangdong, China. With 4 production bases total 150,000M2 workshops and over 900 workers. It takes bathroom vanity, led bathroom mirror and shower door as its flagship and drives the development of related industries, including faucets, showers, toilet etc., forming a diversified industrial pattern. It is a comprehensive large-scale enterprise integrating R&D, design, production and marketing. Our products export to more 50 countries, with more than 1,000 exclusive shops worldwide.

JATAII is the leading bathroom vanity manufacturer in sanitary ware industry. It’s our goal to bring innovative designs and quality products to our valued customers. After almost 20 years of hard working and persistence, we leads the industry in quality, fashion and styling, extravagates with outstanding customer service care, has the exceptional experience and rigorous quality standards to ensure the end products to exceed your expectation. If you are going to shop bathroom vanities or wholesale bathroom vanities from China, JATAII is the best choice for you.

Professional Service Team

Continuous product innovation & product quality are very important, but so is service. Our service team is consisted of designer team, marketing team, sales team, corporate business school & aftersales team. They always adhere to the company core values of gratitude, integrity, pragmatism and innovation to serve customers. They use their own professional to bring convenience and value for the customer, help them solve any problems. if you are going to shop bathroom vanities or wholesale cabinets from China, please contact us immediately.

FAQs

After your understanding of us as above, if you want to cooperate with JATAII perhaps you will have the following questions.